JL-W

Custom Machined Wristwatch

Overview

After designing and making for other users for the bulk of my academic career, an open project presented an opportunity to build something for myself. Something that sparked a passion and was made to last.

Tools

Brideport Mill / Metal Lathe

Bambu A1 Mini

Autodesk Fusion

Environment

Metals ii

Date

2025

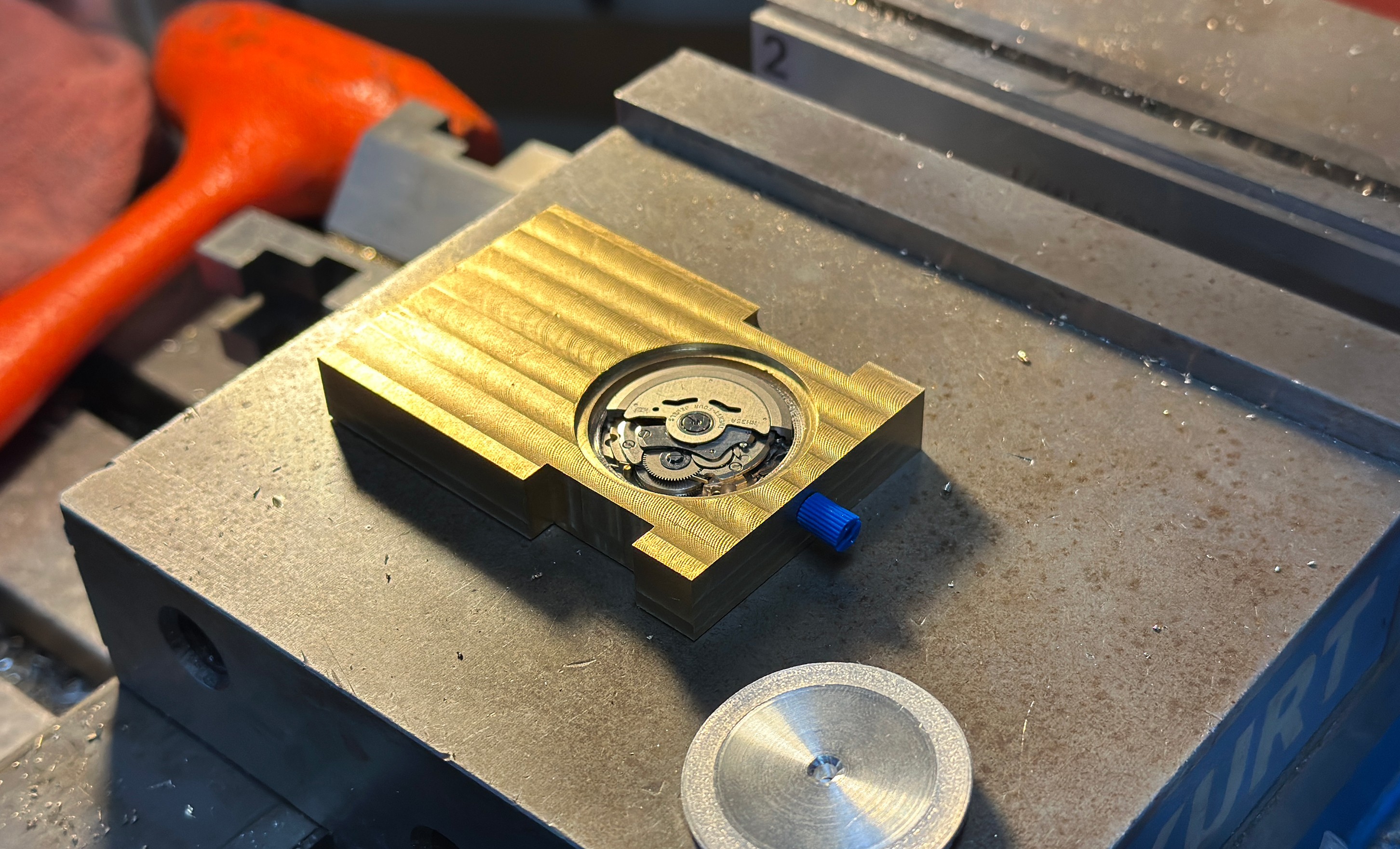

Designing a watch case around a Seiko NH35 movement, I created a fully functional wristwatch. The main body is composed of three parts—the bezel, case, and backplate—with 3D-printed gaskets between each layer to create a tension fit that allows for easy disassembly.

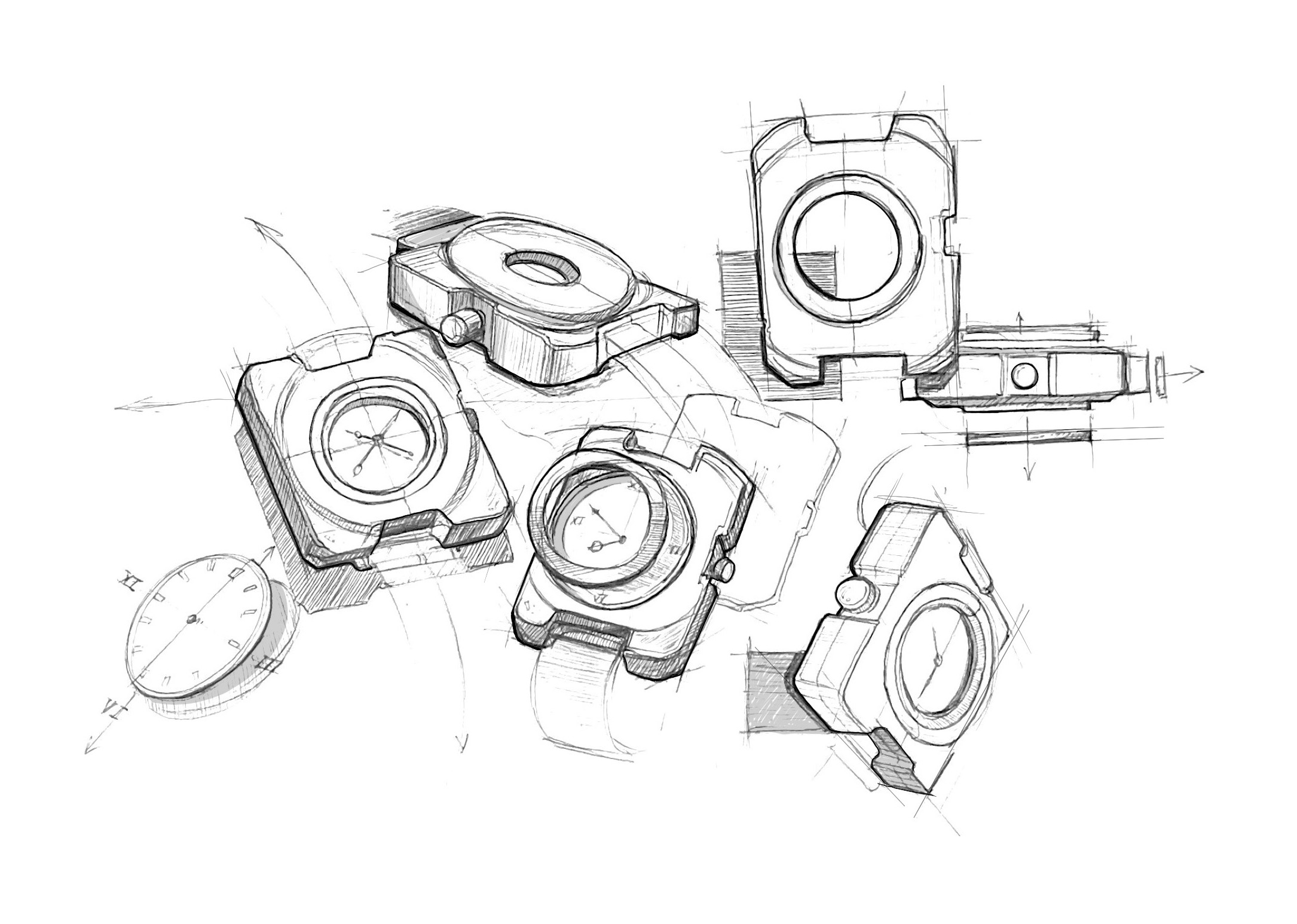

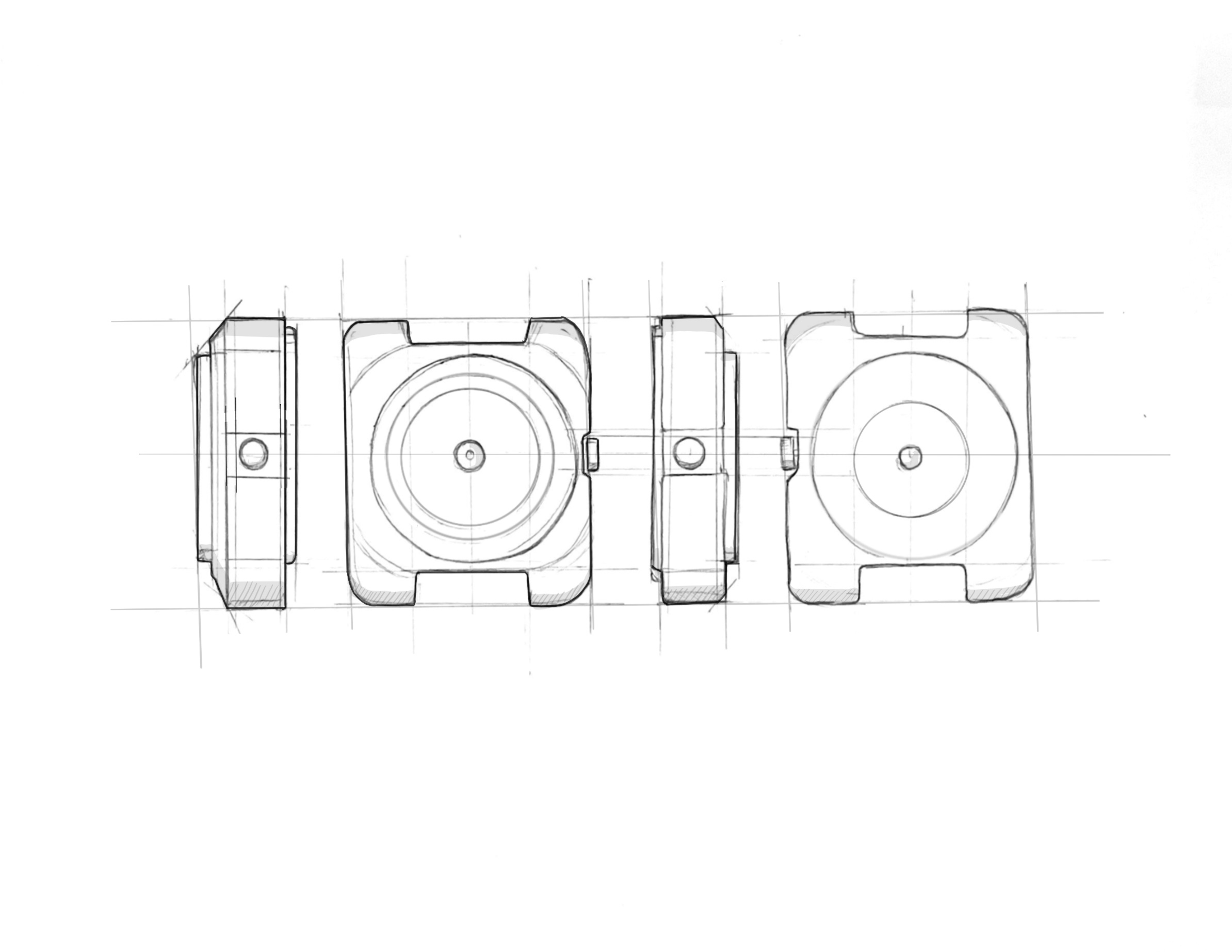

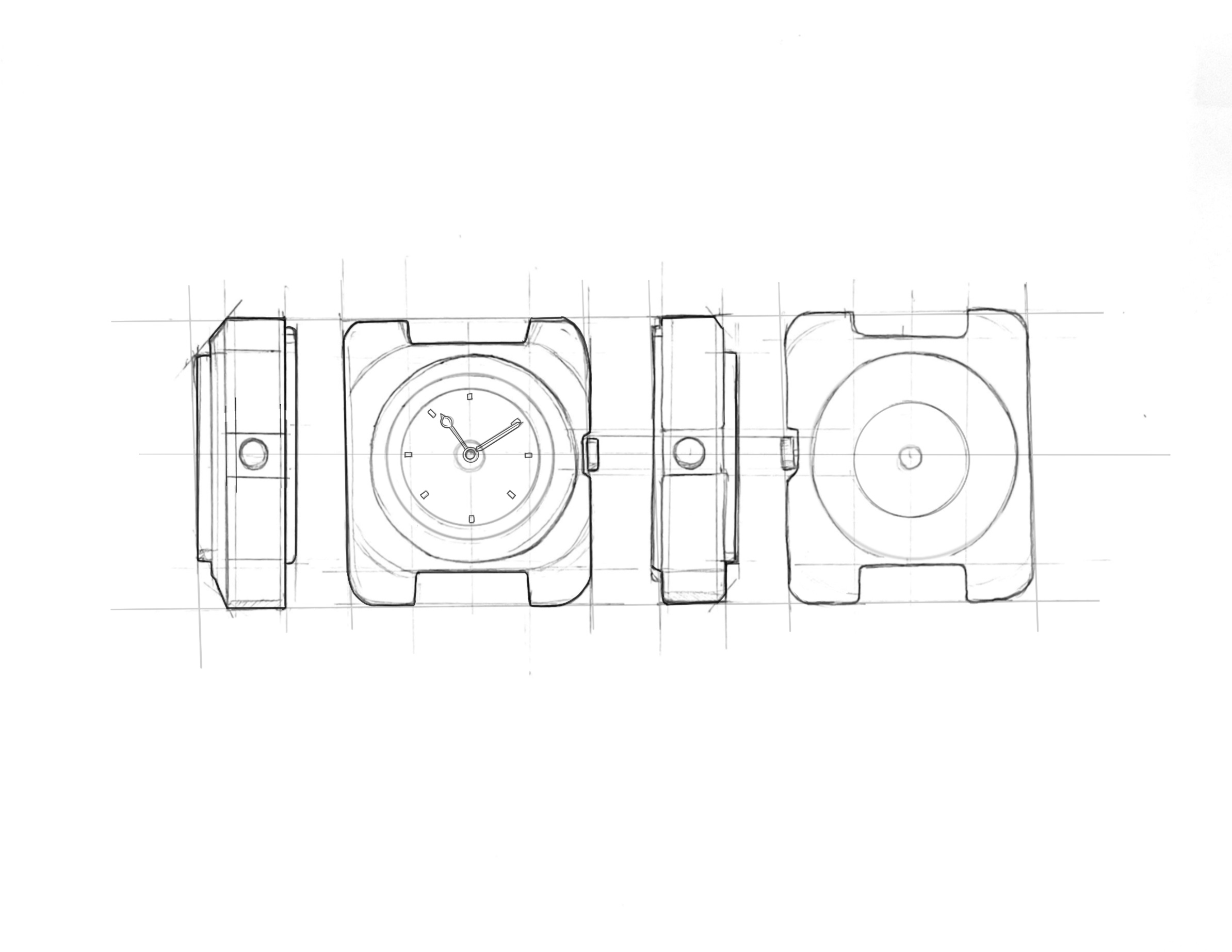

After some quick orthographic and form sketches, I created a rough 3D model of the movement I would use and sculpted around it to get a loose estimation of my dimensions so I would know how much material to order.

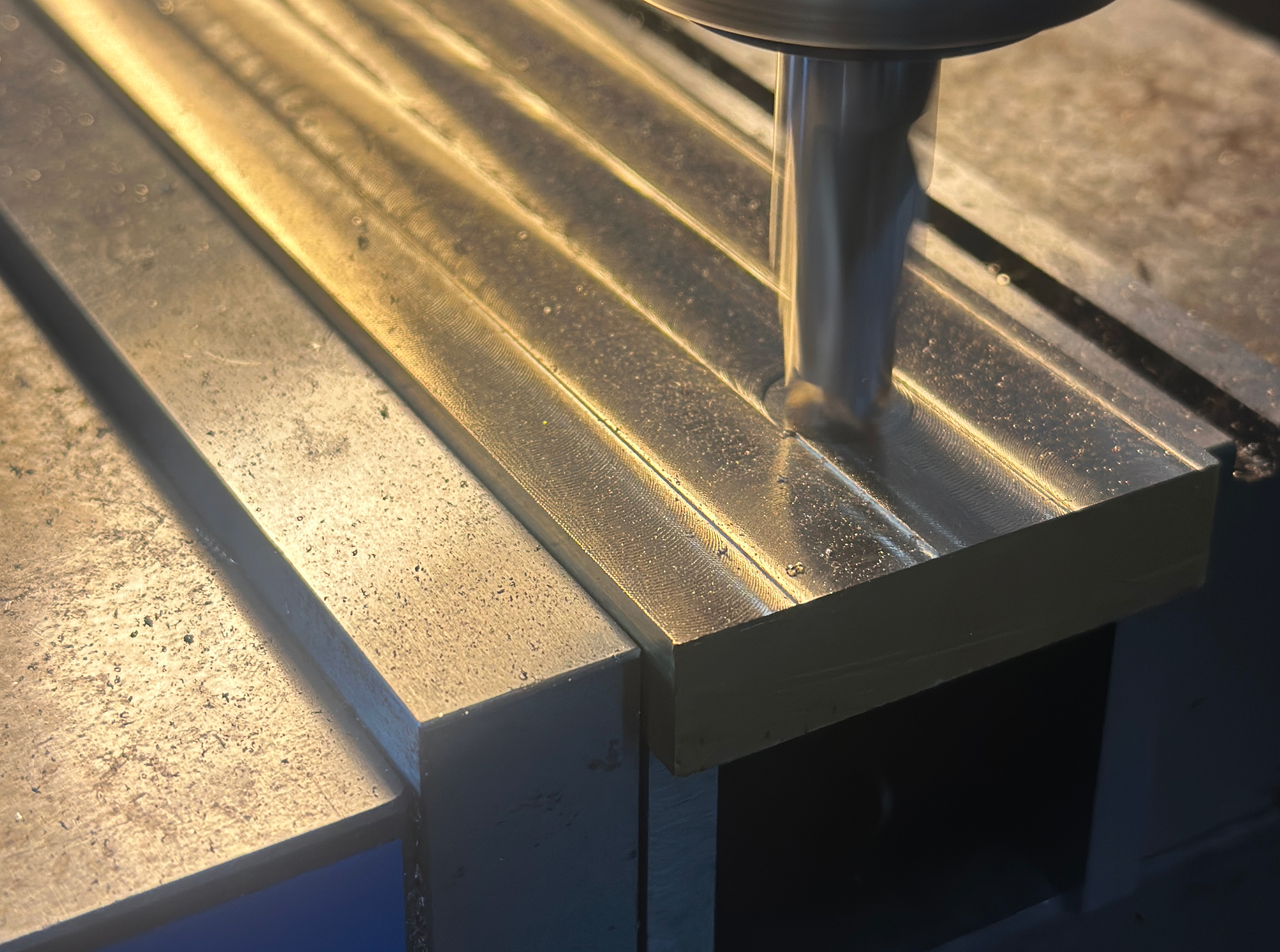

To start the physical fabrication, I took apart a cheap quartz watch from Amazon and started machining around it on some scrap aluminum. Although the final mechanism and fabrication would be much more complicated, this early iteration helped provide insight to what tolerances and speeds I should aim to machine.

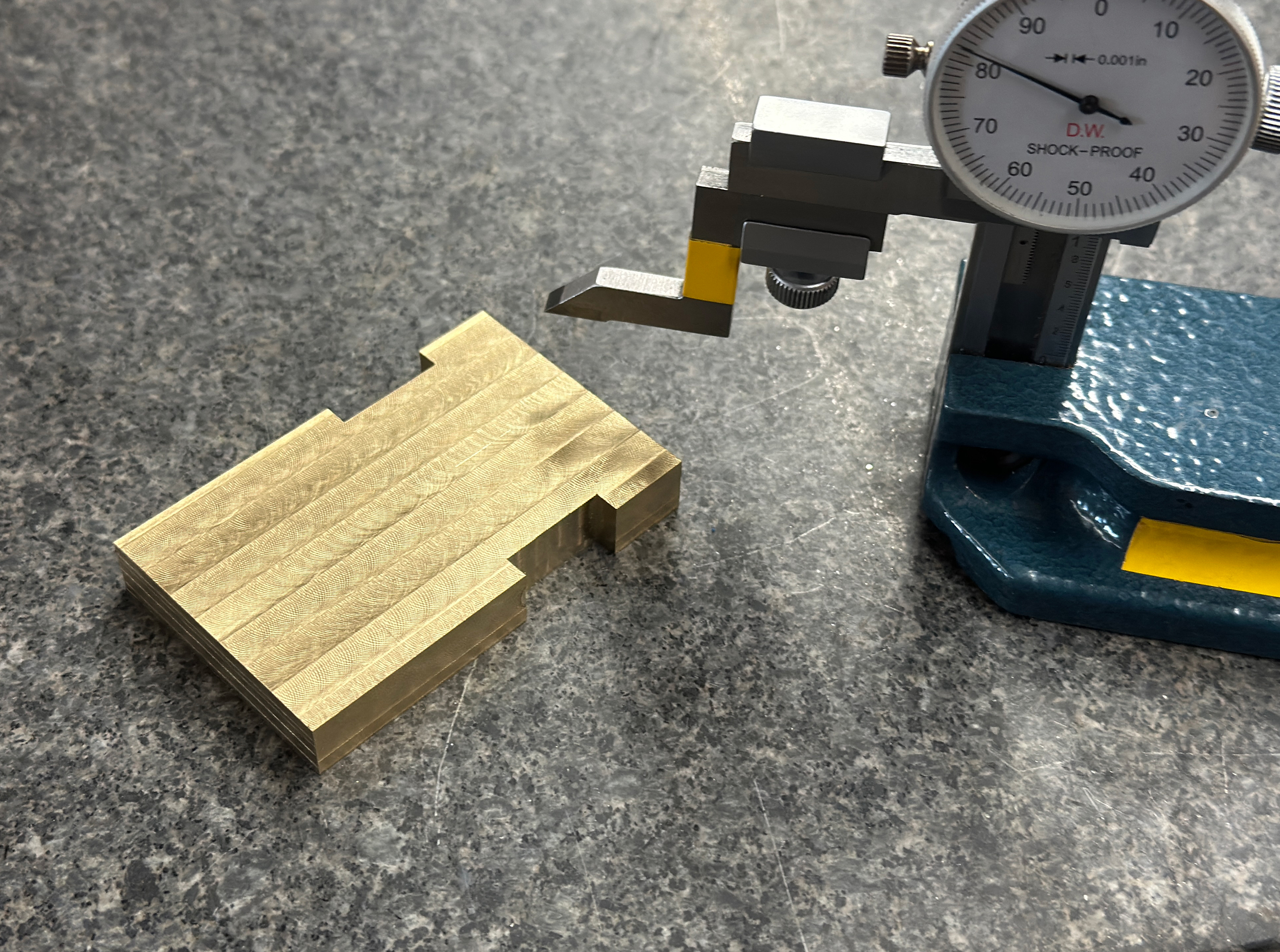

Once I was comfortable on both the mill and lathe, I began the final model. I decided to use a softer brass for the main body, along with aluminum on the bezel and caseback for a unique two tone look. The first and most important step was to drill the main hole where the movement would sit. Having to create an exact diameter with stepdowns, I marked each cut with a micrometer and height gauge.

Once I could secure the movement, I swapped between the mill and the lathe in order to shape the watch. Gluing some scrap aluminum to the brass case allowed me to switch between the tools easily, allowing me to work both radius and angular shapes into one form. The final steps before assembly were creating lug pins with piano wire and laser engraving a custom dial on a piece of thin cut aluminum.